CFRP Processing: TIER 1 Supplier ACE Relies

on HG GRIMME CNC Machines

Class-A quality visible parts and structural components: TIER 1 supplier ACE primarily manufactures carbon fiber reinforced plastic parts for premium manufacturers using the closed Resin Transfer Molding process. For the subsequent finishing of components for Lamborghini, Porsche, Aston Martin and others, the company from Lake Constance mainly uses dual-table CNC machining centers with shuttle systems from HG GRIMME SysTech. High dust generation and three-shift operation place significant demands on the machines.

by F. Stephan Auch, freelance technical journalist, Nuremberg

Processing of Composite Components at ACE: Success Through Shuttle Technology

The first CNC milling system for composite parts, commissioned by ACE Advanced Composite Engineering GmbH in Hagnau in 2008, was still a single-table machine. Peter Klaus Gröschl, Production Manager and one of the Managing Directors, would not make this choice today. With only one table, the spindle remains idle for approximately 40 to 45% of the possible running time due to setup interruptions.

All subsequent purchases feature two tables: while a component is being processed on the first table, the second can be loaded and unloaded outside the cabin in parallel with production time. The shuttle then moves the tables through the system between preparation station, work area, and unloading point.

“The shuttle system is excellent; it reduces downtime to just two to three percent, which means only a few minutes per hour,” Gröschl enthuses. With three-shift operation across six working days, the productivity increase through the shuttle operation is enormous.

ACE produces ninety percent CFRP parts

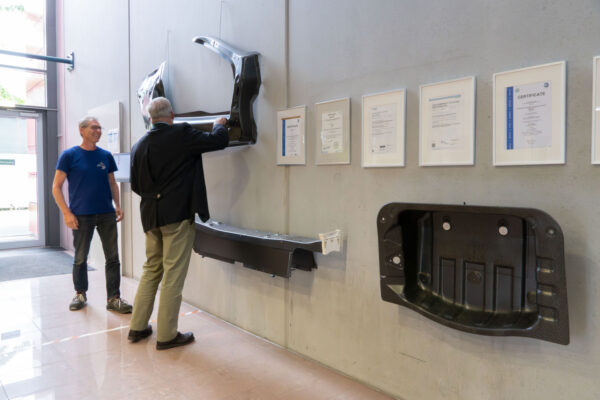

Ninety percent of the components and assemblies that ACE manufactures are made from carbon fiber reinforced plastic (CFRP). About two-thirds of these are visible parts, predominantly for automotive bodies, especially fenders and hoods. One-third of the CFRP components are structural parts such as monocoques for the powertrain, battery trays for electric vehicles, and coverings for B-pillars and center pillars. Even glass processed by ACE can be reinforced with the material to reduce shattering during crashes.

Most customers come from the automotive sector: around eighty percent of the turnover is generated by the composite specialists with customers from the automotive industry, with the remainder coming from aerospace and other industrial sectors.

The customer list reads like an excerpt from the who’s who of automotive manufacturing: alongside Lamborghini, Porsche, and Aston Martin are brands such as Bugatti, BMW, Mercedes, AMG, Audi, and Volkswagen. In aerospace, Airbus and EADS are among the most important customers.

Quality and reliability are part of the DNA

These customers are offered a comprehensive range of services: ACE develops components, produces molds, tools, and prototypes in-house, takes over series production, repairs CFRP components, and manages their recycling and disposal at the end of their lifecycle. “Since our start in 2001, we have stood for the highest quality and reliability. That’s our DNA,” emphasizes Gröschl, who is one of the three founders.

From an initial six employees in Hagnau, ACE has grown to 400 staff members. 140 of them work at the original location, while 260 are employed in Neufrach, a district of Salem located twelve kilometers away, which is known for its boarding school.

Carbon parts are manufactured from multiple shells

There is busy transport activity between both addresses: in Hagnau, the textile preforms are manually cut and prepared as CFRP layups; in Neufrach, the presses with the molds are located. The textile layers are placed into these molds, injected with resin, and baked into shells. “Nine out of ten parts are manufactured using this closed RTM process,” reports Gröschl.

Most carbon components consist of two separately manufactured outer and inner shells; some variants contain a third layer. Since the edges of the raw parts do not meet the specifications, they must be finished in Neufrach.

Subsequently, the shells are bonded to form a complete part, which finds its way back to Hagnau after an intermediate stop at an external paint shop. There, the employees subject them to a final quality control before delivering them to the customers’ assembly lines.

Contour milling precedes painting

“For us, finishing means that contours and cutouts of the shells are milled,” explains Pius Schlegel, Master Model Maker in Construction/Maintenance. He handed over this position to his successor in February 2024 after 21 years at ACE. As a part-time retiree, he continues to support his colleagues.

The dimensions of the components to be processed measure up to 2,000 x 2,500 mm, with thicknesses between 1 and 3 mm. Typically, batch sizes range from 500 to 10,000 pieces – sometimes it’s just forty sets of left and right fenders for a Porsche sports car. “Even though finishing surface parts is more complex than structural elements, we are in a comfortable situation with tolerances of two to three tenths of a millimeter,” Schlegel admits.

Mastering the challenges of CFRP processing

Dust is the biggest challenge.

The greatest challenge in professional CFRP processing results from the dust generated during machining. One of the problems that ACE had to overcome was electrical charges that regularly caused short circuits in the control cabinets during the initial period. “It took us a while to discover that the electrically charged carbon dust was the cause,” recalls Schlegel. The control cabinets are now better sealed and protected, and a continuous airflow blows the particles away from the electronics to the outside.

The CNC machining centers are also heavily affected by the dust. To contain its spread, the HG GRIMME SysTech machining centers are completely enclosed, and an extraction system removes many airborne particles directly in the cabin. Additionally, the components are cleaned once more by hand with high pressure after machining. “This way, we have gotten the problem under control,” states the experienced model making master.

What cannot be prevented is that during CFRP processing, wear parts such as the milling spindles in particular are heavily affected. Joachim Schropp, the responsible sales representative at HG GRIMME SysTech, therefore advises users to always keep spare parts for the most important machine components in stock.

Dynamic and very accessible

ACE has also followed his advice, acquiring in 2024 the latest of three identical 5-axis CNC portal milling systems of the type P-S-F (20-25)/S with two tables and shuttle from HG GRIMME SysTech. The other two have been in use at the company since 2023 and 2016.

All milling centers are suitable for workpieces with external dimensions up to 2,000 x 2,500 x 650 mm, which can be processed exceptionally dynamically thanks to rapid traverse speeds of 50 m/min in X/U/Y and 30 m/min in Z. The spindle offers a power of 6.5 kW and can be equipped from two tool magazines with twelve slots each.

The two tables and the shuttle result in the machines having an impressive length of nearly 11 meters with a width of just under six meters. While the space requirement is not small, “the machine table and milling head are very accessible from all sides and from every position,” Schlegel emphasizes. This is not the case with machines from many competitors.

Switching between systems is simple

All three milling centers from HG GRIMME SysTech are equipped with Siemens 840 dsl controls, “so an operator who has been trained once can operate all machines,” Schlegel emphasizes. The switch between the systems is simplified by the fact that all tables have the same hole pattern with a fixed zero point: “This way, we have minimal setup times and can precisely finish CFRP parts on all HG GRIMME machines to the same degree.”

Production Manager Gröschl also praises the solidity and reliability of the systems. He also appreciates the manufacturer’s service: “We always find a contact person there who seeks the fastest possible solution.”

The modular design of the systems also simplifies rapid adaptation for special requests. His conclusion: “At HG GRIMME, they understand industrial CFRP processing, the communication is at eye level. The company is down-to-earth. We enjoy working together.”

Case Study

CFRP milling and machining – 5-axis CNC machine – Interview

A fine line between nightmare and lightweight vision

More

HG GRIMME SysTech – swissplast en

HG GRIMME SysTech and swissplast group – the similar mentality of the two family-owned companies plays a role, as can be seen at the Gotha location.

More