Positioning components exactly – fixture construction

for CNC machining centres

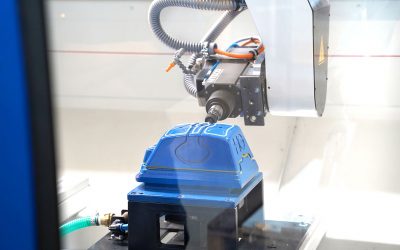

When you are milling components, it is essential for them to be positioned exactly and stably on the work table – this is done using milling fixtures which we design and manufacture for you to suit your component and your CNC machine. This is because it is only by having a cleverly designed milling fixture that your components can be fixed on the work table with absolute precision and picked up correctly so that the positioning is always identical. The milling spindle continuously approaches the same point on each workpiece, thus ensuring consistent machining. The appropriate milling fixture can maintain the geometry while preventing any deviations. This means the quality will be exactly the same for each component. In addition, we do of course also develop the appropriate CNC program for your workpiece in our Programming department.

“If you also equip our universal CNC machining centres with a component-specific fixture, use an optimised processing program and high-quality milling tools, the component will be machined with absolute precision.”

“The fixture that fixes the component in place is an extremely important element for the overall machining process and should be considered in the design of any CNC machine right from the start. Subsequent retrofitting of different fixtures is also possible. Our customers are often amazed at the improvement that this makes to the outcome, which is then quickly apparent on the workpiece.”

Michael Trautwein, Head of Programming

From a virtual component to the perfect milling fixture

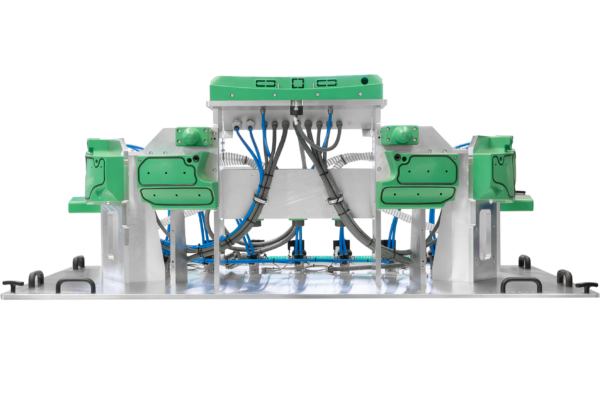

Fixture construction starts with you sending us your CAD data or drawings of the component as a virtual 3D design. We then verify the geometry of the component and start developing the milling fixture. Our CNC machining centres can be equipped with any milling fixture. With any equipping, it makes a lot of sense to have the right fixings, such as a vacuum fixing, pneumatic clampers and monitoring of the mounting. Components with sensitive or delicate surfaces (lacquered, coated or polished) can be carefully held gently on the work table using special fixings.

Additional monitoring of the milling fixture by means of proximity switches also minimises the risk of the operator placing things in the wrong place. Only once the component has been placed on the milling fixture correctly is a release signal issued to the control system to start the cutting or milling process.

Milling fixtures – a crucial factor in the milling quality

A component can only be milled with absolute precision if it is fixed on a fixture with the optimum design. You do not need to just settle for any old milling fixture – we at HG GRIMME SysTech know exactly where the machine connections need to be, make sure the workpiece is accessible and adapt the screw fitting of the milling fixture exactly to suit your CNC machining centre. This allows us to guarantee a high-quality workpiece and an optimised milling process.

Whether you require a milling fixture for postforming or for complex scoring tasks – we can design the appropriate fixture for you. Before we hand over the milling fixture we have designed to our production team, you receive draft designs for approval. In this step, it is thus possible to incorporate special requests or changes.

During the process of approving your CNC machine, all the functions of the milling fixture are explained to you. With a more complex fixture construction, the Programming or Design department will also visit you on site.

Fixtures constructed from high-quality materials for CNC machines

Our milling fixtures are made from high-quality materials such as aluminium and polyurethane foam. Aluminium is particularly suitable because it has a low weight and yet is still stable. On the other hand, polyurethane foam can be adapted perfectly to your component because it is easy to process.