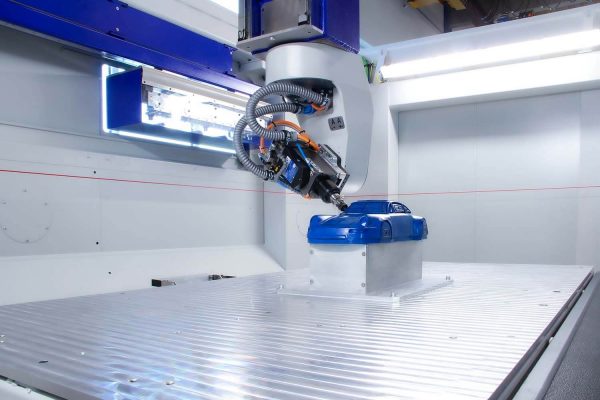

6-axis CNC milling machine with stitching unit – high throughput, measurable precision – perfect defined weakening lines

The 6-axis CNC stitching machine from HG GRIMME SysTech has been developed specifically for the automotive industry and optimised for producing defined weakening lines for airbags. Thanks to the innovative stitching method and the high-speed processing, the CNC milling machine allows rapid manufacturing while still maintaining a high level of precision and safety and a low level of machine wear and tear. The perfect defined weakening lines in instrumental panel dashboards and steering wheels provide the very best protection for passengers. With our many years of experience in the automotive sector, we can meet any customer specification and produce CNC machining centres for high-quality products used in the car industry.

Airbag components: Defined weakening lines with a high-speed process

We developed the 6-axis HSC CNC stitching machine specifically for the automotive industry and to meet the high quality standard that the car manufacturers demand for airbags. The CNC machine delivers very short cycle times with measurable, outstanding milling results. It mills using a high-speed process without compromising on the safety of the airbag.

Secure stitching thanks to precise milling of weakening lines for airbag components

The precise milling of invisible weakening lines in the stitching process weakens the material to a precisely defined residual wall thickness. The milled plastic component, such as the instrumental panel – the IP dashboard – in the front section of the car, weakened sections open precisely at the defined weakened point when a predetermined pressure is applied to the airbag. The airbag explodes.

Faster production with low wear on the machine

The 6-axis CNC milling machine in combination with the stitching unit and the customised milling tool make it possible to weaken the material in a precise and measurable way during the stitching process to produce different thicknesses on a single component. The sixth axis performs the high-speed stitching. This ensures there is a low level of wear on the machine and speeds up production at the same time. This high-speed process results in rapid cycle times without having to make any compromises on safety.

Perfect defined weakening lines for airbags on the IP dashboard or steering wheel

The CNC milling machine makes it possible to quickly manufacture high-quality products so that airbags can be fitted safely and securely. For example, instrumental panels in front of the passenger or steering wheels are equipped with perfect defined weakening lines for deploying the airbag. The 6-axis HSC CNC stitching machine satisfies all the requirements of the automotive industry, thus guaranteeing passenger safety.

Many years of experience with production processes in the automotive industry

Individual advice and customised solutions for safe airbags made in Germany

Our many years of experience in processing parts precisely for airbags allow us to implement any specification for our customers. We know the demands that are placed on products and production processes in the automotive industry. Our machines are developed, designed and made in Germany. Our customers receive advice and support from experts and engineers. Following commissioning, highly skilled staff working in the Service department are available to support you. The Service department is based at our main factory and can answer any technical questions.

The automotive industry – 35 years of experience – HG GRIMME SysTech

Airbagbearbeitung

Die Auswahl der richtigen Schneidetechnologie ist entscheidend und abhängig vom Material. Alle Verfahren mit Rückverfolgbarkeit dokumentierter Prozessparameter.

More

CFRP milling and machining – 5-axis CNC machine – Interview

A fine line between nightmare and lightweight vision

More