Production processes for CNC milling using

CNC machines from HG GRIMME SysTech

From wood and metal, plastics, composites to modelling materials – every material used in CNC machining presents different demands for milling tools and machining centres. At HG GRIMME SysTech we have in-house specialists for every conceivable production process who know everything there is to know about your materials and can work with you to combine the right process technology with the appropriate CNC machining centre – from CNC milling and water-jet cutting to blade cutting.

CNC milling – the technology

behind our core expertise

When we mill your material, we apply the greatest possible cutting speed to your workpiece in order to guarantee that milled parts can be manufactured efficiently. Together with an optimum feed motion, this allows us to achieve a very good quality of surface finish for your workpiece. When we do this, we do of course also consider the specific requirements that each material has – and we are very happy to pass on our expert knowledge to you. For example, plastics react differently to thermal changes and mechanical influences when they are being processed in a CNC machining centre.

Whatever material is used to produce your milled parts, we always know precisely what is required. This is because HG GRIMME SysTech excels in milling high-precision shapes with a perfect quality of surface finish. CNC milling is our core expertise!

Milling – the machining

production process

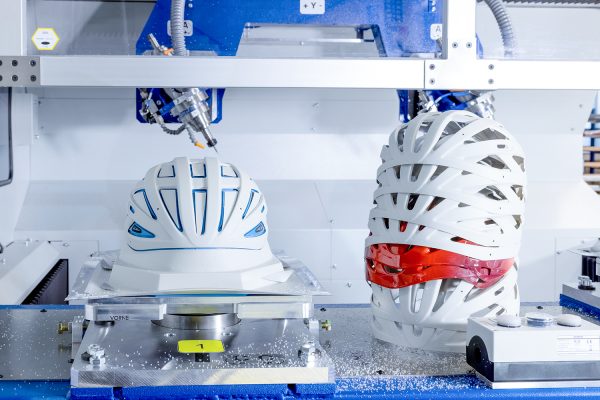

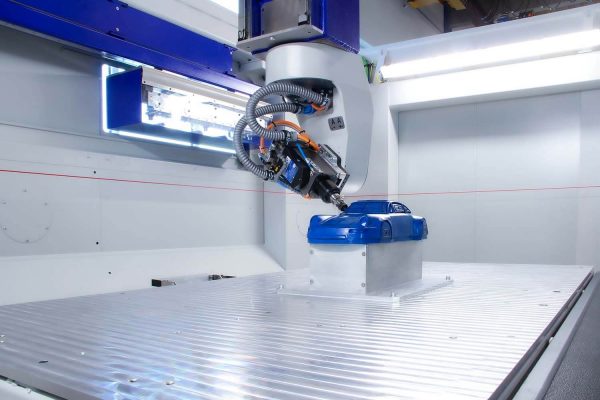

When metals, composite materials, plastics, modelling materials and wood are milled, special milling tools are used on automated CNC milling machines. With a choice of many different options available to you, all CNC machining centres from HG GRIMME SysTech can be adapted specifically to suit the particular production process and the relevant material. This makes the CNC milling even more efficient and you get an optimum rate of material removal.

Numerically controlled CNC milling

The milling is done by numerically controlled CNC machining centres. The individual axes are monitored by sensitive sensors while the distances travelled are measured by glass measuring blocks. Each axis can be controlled individually or jointly. At the same time, the feed motion can also be determined.

All milling machines from HG GRIMME SysTech have at least 5 axes. Different design options allow the CNC machining centres to be expanded to have up to 14 axes. In addition, thanks to optional tool changers and different versions of magazines, the production process operates in a completely automated, optimised way.

Water-jet cutting – cutting

without exposure to heat

When other cutting processes reach their limits, the CNC water-jet machine with its 5-axis technology gets to work. The “cold” process means that it operates without producing any sparks or thermal reactions. The CNC machining centre for water-jet cutting developed by HG GRIMME SysTech can carefully process relatively soft materials.

5-axis CNC water-jet cutting machines

with pure water

Our 5-axis CNC water-jet cutting machine features innovative water-jet technology that uses pure water, which makes it particularly clean and environmentally friendly. The jet of pure water combined with a high cutting speed allows even delicate contours to be machined. Soft materials such as rubber, foams or textiles in particular often cause the milling tools to wear faster or cannot be milled at all. This is precisely where the water-jet cutting method comes in: For the very thin jet of pure water is approx. 0.1 mm wide and this allows these materials to be processed effectively. To guarantee a good cutting result, the nozzle needs to be kept free of any limescale. To achieve this, the water is first treated to make it pure so that no limescale is visible on the workpiece and equipment is preserved for a long period of time.

Blade cutting and scoring

Blade cutting or scoring is used, for example, to produce slush skins for dashboards in passenger cars.

Scoring is a process used to mark predefined airbag tear lines on components inside vehicles – such as dashboards (3D) or decorative cover materials (2D). The respective slush skin is reduced with a fixed blade down to the residual wall thickness or cutting lines which weaken the slush skin at defined points are introduced. Scoring can be used to process laminated materials (so materials which have multiple layers joined together) but also many different plastic materials. Choosing the appropriate cutting technology is absolutely crucial and depends on the material that is going to be processed.

Cold blade or ultrasonic –

CNC blade cutting machine

The advantage of scoring in the ultrasonic range is that the oscillating blade heats the material and welds both cut sides at the same time. This means the material remains cut without binding together again. By contrast, the “cold” blade is used when there should not be any welding. Blade cutting is absolutely precise thanks to high-precision, linear path measuring systems in the axes. Every single component can be tracked using automatically generated LOG files which accurately document all process parameters.

Weakening by milling

Targeted weakening on the back of hard panels, such as those used on car dashboards, can mill defined break points for airbags into them. The rest of the panel is retained in wafer-thin form and is no longer visible on the front.