The new generation of our

5-axis CNC portal milling machines

More power, higher dynamics, optimized design.

With the revised generation of our CNC portal milling machines, we have focused specifically on the factors that matter most in everyday industrial use: power, speed, rigidity and cost efficiency. The result is a noticeably more capable CNC machine.

Feel free to contact us: ☎ +49 8241 96080 or ✉ sales@hg-grimme.de

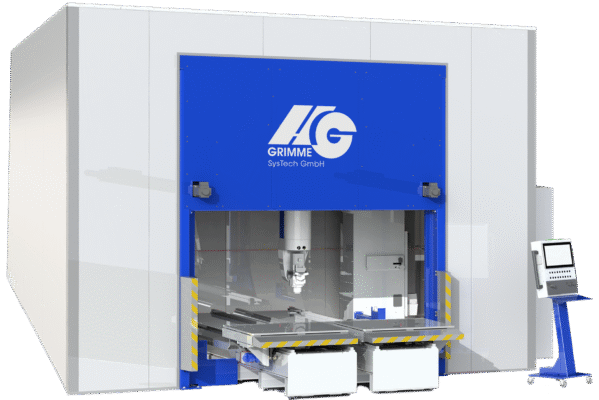

HG 5-Axis CNC Portal Single Milling Machine P-S-F

HG 5-Axis CNC Portal Tandem Milling Machine P-T-F

The CNC portal milling machine achieves excellent surface quality with maximum precision, even at high dynamic performance. With minimal setup times, high traverse and cutting speeds, and optimized feed rates, this milling centre enables high-speed machining that makes CNC milling more economical.

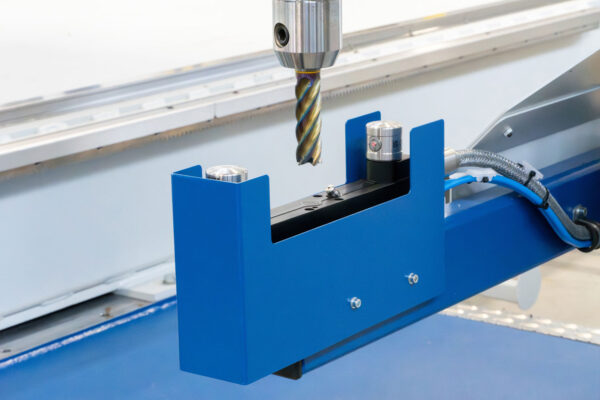

Portal milling machine with a powerful milling spindle

More spindle power for demanding machining tasks

For the first time, the new generation of portal milling machines is equipped with the Hiteco QE-2 motor spindle. With a torque of 11.9 Nm and an output of 15 kW (S6), it significantly expands the available performance range and enables higher material removal rates during machining. Compared to the previous QD-2 spindle, this results in shorter machining times and increased process reliability.

Expandable tool changer for up to 20 tools

Proven tool handling – flexibly expandable

The standard tool changer is clearly designed for everyday industrial use. Ten tool positions for tools up to Ø 70 mm, 300 mm in length and weighing up to 5 kg each cover common applications. Optionally, the system can be expanded with a second tool changer to specifically increase tool capacity and adapt the machine configuration.

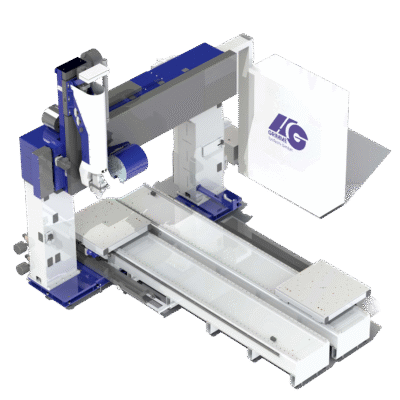

30% higher rigidity for precise industrial machining

Noticeably increased rigidity of the machine structure

The traverse, column, and the Y and Z axis carriers have been newly designed. This has increased the rigidity of the machine structure by up to 30%, resulting in improved dimensional accuracy and stable machining even under high cutting forces. At the same time, the design has been simplified, which has a positive effect on maintenance requirements and overall costs.

Significantly highertravel speeds

The linear X and Y axes now reach up to 80 m/min, while the Z axis reaches up to 60 m/min. This increases the dynamics of the CNC portal milling machine and reduces non-productive time in the machining process. The rack-and-pinion drive design allows for flexible machine layouts, particularly for large components and special dimensions.

Designed for stable continuous operation

The revised portal structure with optimized internal cable routing increases mechanical stability and provides improved protection of sensitive components against contamination. This reduces wear and unplanned downtime. At the same time, the machine structure remains service-friendly and is designed for continuous industrial operation.

Enclosed shuttle axes for chip-intensive applications

Enclosed shuttle axes for chip- and dirt-intensive applications

The fully enclosed design of the shuttle axes allows for long travel distances at high speeds while reliably protecting the mechanics from dirt and chips. This significantly reduces wear and maintenance requirements

Conclusion

With the new generation of our CNC portal milling machines, performance, dynamics and structural stability have been further developed in a targeted manner. The combination of higher spindle power, increased rigidity and optimized motion sequences provides the basis for productive, stable and cost-efficient CNC manufacturing processes – even for large components and demanding applications.

Questions & Answers on the CNC Portal Milling Machine

For high productivity requirements, the portal milling machine can be equipped for alternating operation with two worktables. In this configuration, the CNC machine operates in tandem mode. While machining is performed on one table, the second table is positioned outside the machining area for loading and unloading. This significantly reduces idle times. For machining large components, the tandem tables can be coupled.

This machine configuration is particularly suitable as a basis for automated manufacturing solutions.

Questions & Answers on the CNC Portal Milling Machine

The design of the CNC portal milling machine is focused on stable processes, short non-productive times and reliable continuous operation. These characteristics are essential prerequisites for automated manufacturing concepts. An implemented example of an automated CNC system is documented in a customer application report:

https://www.hg-grimme.de/en/Best Practice Reports/automated-cnc-systems/

Higher spindle power provides additional performance reserves for demanding machining tasks. This makes it possible to achieve higher material removal rates without compromising process stability. At the same time, machining strategies can be designed more efficiently overall, particularly when processing larger workpieces.

The increased rigidity ensures that the machine remains stable even under high machining forces. As a result, the forces generated are reliably absorbed and precise results are consistently achieved.

Higher travel speeds shorten positioning and movement times between machining steps. This reduces non-productive time in the overall process. The rack-and-pinion axis design also supports flexible machine concepts, for example when machining large components or special dimensions.

The standard tool changer is designed for common industrial applications and accommodates ten tools. It accepts tools up to Ø 70 mm, 300 mm in length and weighing up to 5 kg. If required, the tool capacity can be expanded by adding an additional tool changer.

The machine structure is designed to protect sensitive components from chips and contamination. Optimized cable routing and protected assemblies reduce the direct impact of dirt on the mechanics and drive systems. This supports stable operation with predictable maintenance intervals.

Automated manufacturing requires stable processes, minimal non-productive time and reliable continuous operation. The design of the CNC portal milling machine supports these requirements at machine level. A realized example of an automated CNC system is documented in a customer application report:

https://www.hg-grimme.de/en/Best Practice Reports/automated-cnc-systems/

The design of the CNC portal milling machine focuses on stable processes, short non-productive times and reliable continuous operation. These characteristics are fundamental prerequisites for automated manufacturing concepts. A realized example of an automated CNC system is documented in a customer application report:

https://www.hg-grimme.de/en/Best Practice Reports/automated-cnc-systems/

Best Practice Reports

CFRP milling and machining - 5-axis CNC machine - Interview

A fine line between nightmare and lightweight vision

More

HG GRIMME SysTech - swissplast en

HG GRIMME SysTech and swissplast group - the similar mentality of the two family-owned companies plays a role, as can be seen at the Gotha location.

More