Automation in milling with CNC machining centres

Automation all the way along your value chain – this is a key issue that is very relevant across all sectors of industry and is also being accelerated by the global pandemic and the shortage of skilled workers. This is because the pandemic in particular has made outsourcing to other countries or external partners a less attractive proposition. The incentive to manufacture your own products is high and many companies are embracing automation in order to make themselves competitive on their own, in their own country, usually within Europe.

FAQ – Automation of CNC Milling Machines & Machining Centers

Our solutions range from industrial robots for automated loading and unloading, to cobots that can flexibly support multiple machines, all the way to automatic clamping systems and camera-based part recognition. We develop customized solutions tailored to your workpieces and workflows—whether for new installations or retrofitting existing machines.

You receive a fully operational automation solution, tailored from the outset to your requirements. This includes consulting, planning, CNC system design, the appropriate industrial robot or cobot with custom grippers and clamping systems, software integration with your CNC controls, as well as installation and commissioning. You don’t need to worry about system interfaces—everything is delivered from a single source.

Every production facility is unique, so we focus on seamlessly integrating our automation solutions into your existing setup. This covers not only space requirements but also material flow, operator access, safety, and your established workflows. We assess your spatial and technical conditions in detail and develop a solution that fits as smoothly as possible.

If space is tight, we design especially compact automation units or flexible layouts. We also factor in connections to existing machines, conveyor systems, or IT infrastructure from the very beginning. The result is an automation solution that complements your production, not something that feels out of place.

We start with a joint analysis of your production and develop a proposal—optionally visualized with a simulation. Once you approve the concept, we handle implementation and support you through to commissioning—and, of course, with ongoing service afterwards. This ensures your CNC automation works reliably in daily operations.

Our systems are particularly designed for plastics, composite materials such as CFRP/GFRP, aluminum, and model-building materials. We supply companies in the automotive industry, aerospace, leisure sector, sanitary technology, boat building, and many other fields. We have extensive experience especially in automated trimming and milling of composites.

A common challenge is the precise handling of parts with different shapes or stacked components. We address this with custom grippers and camera-based part recognition. We also solve issues like accessibility and minimizing setup times with practical, tailored solutions—always matched to your production.

Depending on the scope, implementation usually takes three to six months. Our technical service team supports you from commissioning through to ongoing operation—both on-site and via remote support.

In practice, automation delivers greater process reliability, consistent product quality, and improved machine utilization—even with varying parts or small batch sizes. Many of our customers say automation allows them to respond more flexibly to staffing shortages and reduces repetitive manual work. This also makes shift work and production outside of regular hours much easier.

Feel free to contact us directly. We’ll take the time to discuss your requirements and provide personal, no-obligation advice.

Be competitive and independent thanks to automation

Sectors such as the automotive industry and the aviation industry in particular are faced with the challenge of embracing electric mobility and transport while at the same time meeting stricter environmental requirements. For example, the level of energy and fuel consumption depends on the weight of a car or the aerodynamics of an aircraft. This means that lightweight materials are particularly crucial in these industries. In addition, the automotive industry needs to produce high volumes of product with excellent quality.

The milling of lightweight and composite materials presents a real challenge because of their characteristics – and this is one of HG GRIMME SysTech’s core areas of expertise. We work with you to develop the optimum solution for competitive and automated milling of lightweight materials. For using sophisticated automation in combination with a powerful CNC machining centre significantly reduces the manufacturing costs – compared to conventional or even semi-automated manufacturing.

Fully automated CNC milling centre –

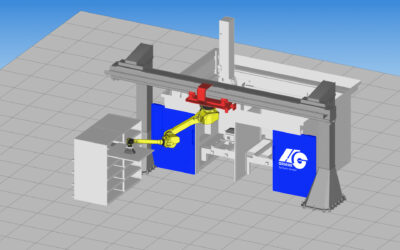

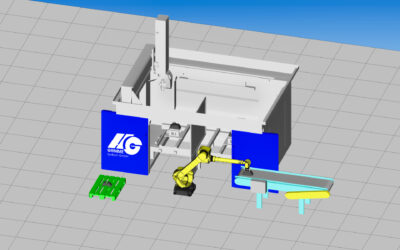

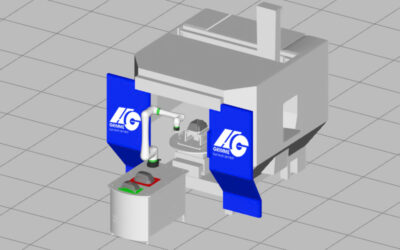

Example of automation: G-DT-F

The milling centre G-DT-F featuring a gantry design and a rotary table operates almost completely on its own. The workpiece is introduced to and removed from the machine by a robot arm which is linked to the CNC control system by a software application. The robot arm can switch between different tools and perform different tasks. For example, as well as changing tools, it can also clean the fixture by blowing off the chips or removing any waste pieces. As soon as the workpiece has been placed on in automated fashion, it is held on the fixture optimally by a vacuum. The position of the workpiece is checked automatically by a camera.

At the same time, the milling process takes place on the other side of the rotary table. The transverse chip conveyor conveys the chips which are produced in the milling process into chip trays. At the same time, the surrounding environment is protected from any milling dust that is produced by an enclosed cabin. In addition, both the room extraction system and the extraction unit on the milling cutter itself minimise milling dust and chips. As well as the protection from milling dust, the tool measurement of the CNC machine is also automated. The tool is immediately replaced when it becomes worn to ensure that a consistently high level of milling quality can be maintained.

An automated CNC milling centre allows you to achieve a huge increase in efficiency with rapid cycles – and you can do this within your own production process. Your skilled staff no longer have to perform routine tasks and can instead focus on their core skills.

Automatic clamping fixtures for greater flexibility

Our CNC milling machine G-DT-F is particularly flexible and can produce many different components thanks to the clamping fixture specially developed by HG GRIMME SysTech. The clamping fixture can be switched to another version of a component at the touch of a button. The fact that the fixture can be rapidly transformed means the set-up times are so short that no storage costs for a second fixture are incurred. The CNC machining centre is therefore not just highly efficient, but also hugely profitable – this is automation that really pays dividends!