The innovative CNC milling machine with a rotary table

and inclined bed for composite materials

HG 5-axis CNC gantry rotary table milling machine/inclined bed G-DT-F/SB

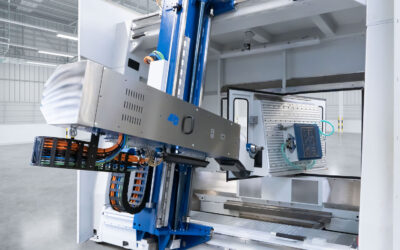

This CNC machining centre with an inclined bed and rotary table is another high-tech innovation for the highly efficient, precise milling of workpieces with a compact 5-axis CNC milling head. The CNC machine is designed specifically for manufacturing composite materials such as GFRP and CFP components and its extraction systems ensure complete safety in the manufacturing process. In addition, the milling machine operates entirely without cooling lubricants so that the composite materials are processed in a dry state.

Frequently Asked Questions about the G-DT-F/SB CNC Milling Machine

After your initial inquiry, we start with a detailed consultation regarding all key aspects such as design, size, arrangement of components, and your desired options. Even at this early stage, you’ll receive expert suggestions and can choose from around 365 configurable options. Together, we define all requirements. On request, we can even carry out milling trials in advance, so you can be sure your part will be manufactured in the required quality.

The machine is modular and can be customized to your needs – for example, with different rotary table sizes, special extraction funnels, or additional automation options like robotic loading.

The machine is modularly configurable and suitable for workpieces with travel paths ranging from 1,800 x 1,600 x 815 mm up to 3,900 x 2,400 x 815 mm, and cube dimensions up to 3,300 x 1,800 x 762 mm. For special sizes, please contact us directly!

The inclined bed design ensures optimal chip removal, makes loading and unloading parts more ergonomic, and improves material flow during the milling process.

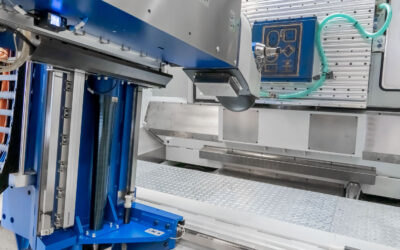

The innovative extraction system removes dust and chips directly at the milling head and at the clamping device. An additional filter unit ensures that nearly 100% of the generated dust is removed and the air is filtered before being returned to the workspace.

Our customers successfully use this machine in the automotive, aerospace, leisure, boatbuilding, plumbing, pipe systems technology, and automated production sectors.

Highly efficient and safe: The extraction systems of the CNC machining centre

To guarantee maximum safety during the milling process, the CNC milling machine can be equipped with various extraction systems. They remove and filter carbon chips and dusts from the CNC machine as soon as they are produced. To extract the dust, large drill holes are introduced into the clamping device and run along the milling contour just a few millimetres apart. In addition to this device, the milling head can also be equipped with a brush extraction system. This ensures that most of the dust does not get into the machine compartment during milling.

In addition, the sealed-off machine cabin can be equipped with a system for extracting particulates. This involves the air from the machine compartment being fed to a filter unit which purifies it to a level of almost 100%. The filtered air is then fed back into the building in order to minimise heating costs in winter. In summer, the purified air can instead be redirected out into the open air. This efficient extraction system works with a high-pressure and a medium-pressure installation which produces different flows.

“In addition, with this version we have safeguarded everything with fire detectors in the extraction unit and filter breakage monitoring. At the top of the machine there is what is known as a police filter which – as the name suggests – acts as a last resort in returning the air filtered back to the building if everything else should fail.” Wolfgang Grimme, Managing Director

Optimum equipment for powerful CNC milling

With its extremely torsionally rigid steel structure, acceleration values of 3,500 mm/min and operating speeds of 60,000 mm/s, the 5-axis CNC machining centre provides the best basis for carrying out powerful and efficient milling of composite materials. The installed high-frequency milling spindles with a power level of up to 16 kW in S6, a rotational speed of up to 36,000 rpm and repeat accuracy of ± 0.04 mm impressively reflect the dynamism and precision of this CNC milling machine.