Automated CNC systems –

Turnkey CNC Machining Centers

Labor shortages and rising wage costs as key drivers: Since the early 2020s, demand for automation projects has been continuously increasing, including in plastics processing. At K 2025, HG GRIMME SysTech, a supplier of CNC machining centers and fixtures, will present a concept for custom turnkey solutions for the automated machining of thermoformed parts. Five scenarios illustrate the range of possibilities – implemented with state-of-the-art CNC machining technology.

“Around 20 years ago, the first customers began developing solutions for automated loading and unloading of machining centers for individual projects. They then approached us to program the PLC interfaces for our milling machines.

Since about 2021, we have been receiving more and more requests asking whether we can offer CNC machining centers complete with automation solutions.

Many customers are new to the topic, which means there is a great need for advice. Our aim is to support you comprehensively on your path toward automation. This also includes an animated simulation that visually demonstrates the advantages of the new CNC machining center.”

Plant Manager / COO, HG GRIMME SysTech

Questions we are often asked

- When we speak of a turnkey CNC machining center, we mean a complete setup consisting of the machining unit, robot, gripper and clamping technology, as well as the corresponding software.

Everything is designed, programmed, and perfectly matched in-house so that the system is ready to run immediately after commissioning.

The variants shown serve as examples from practical applications.

Each automation solution is individually adapted to the workpiece, process, and spatial conditions.

The solutions shown include robots with conveyor transfer, shuttle systems, gantry robots above the machine doors, mobile drawer racks, or cobots supplying one or several machines.

Automation is especially worthwhile for thermoformed parts and composites made from glass or carbon fiber.

It usually becomes economically viable starting at around 50 parts per variant.

Tandem machines with two tables are particularly efficient, as milling and loading can take place simultaneously.

For workpiece handling, we use camera-based recognition systems and specially developed grippers.

This enables even complex or warm parts to be reliably gripped and correctly positioned.

The control system ensures repeatable accuracy during the process.

Our machining centers can be combined with robots from various manufacturers.

Fanuc robots have proven particularly effective because they integrate seamlessly with the control systems we use – usually Siemens or Fanuc.

The best solution always depends on the workpiece and the process.

- From concept approval to a production-ready system, the typical timeframe is between three and six months.

The exact duration depends on the complexity of the robotic technology and the CNC machine variant.

At the beginning, we jointly review the spatial conditions and technical requirements.

Then we develop a suitable solution proposal, which we can visualize with a simulation if required.

After your approval, we take care of implementation – from design and machine construction to commissioning.

We then accompany the production start-up and assist with fine-tuning during operation.

Five Automation Scenarios in Practice

- Robot with conveyor integration:

A robot removes the part directly from the thermoforming machine, places it on a conveyor for cooling and transfer to the machining center. A second robot then positions it onto the clamping fixture.

- Robot with conveyor integration:

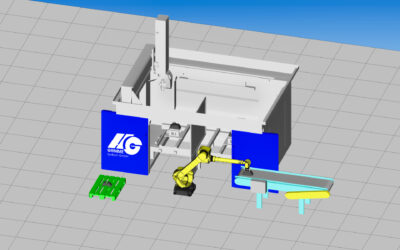

- Robot with shuttle axis:

A robot mounted on a movable axis can service multiple machines, increasing overall utilization.

- Robot with shuttle axis:

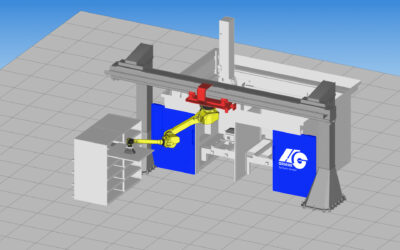

- Gantry system:

The robot is mounted above the machine doors, keeping the workspace clear – ideal for changing fixtures and large parts.

- Gantry system:

Individually adaptable for any CNC machining center.

- Mobile drawer racks:

Operator and machine can access the parts from both sides, improving the production flow.

- Mobile drawer racks:

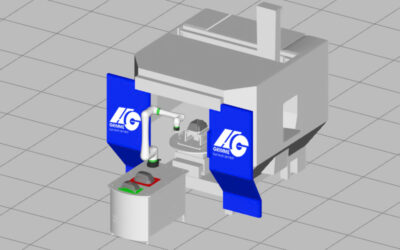

Mobile cobot:

A flexible cobot can load and unload several machining centers simultaneously – highly efficient and space-saving.Consulting:

☎ +49 8241 96080

✉ sales@hg-grimme.de

Overview of Our Machines

Here you’ll find all our modular 5-axis machining centers at a glance.

More

Was ist der Unterschied?

Hier finden Sie Infos zur den Unterschiedlichen Bauweisen: Gantry, Portal und Rundtisch

More

Our 365 options aren’t enough?

We’re happy to develop your very own custom CNC machining center – perfectly tailored to your workpiece.

MoreFrom Machine Builder to System Provide

The company from Wiedergeltingen in the Lower Allgäu region started in 1987 with the development and production of modular CNC machining centers and fixtures for demanding machining of plastics, composites, aluminum, wood, and other model-making materials.

Today, HG GRIMME supplies its machining centers worldwide and provides technical customer service and remote support from several locations.

Today, the machine builder presents itself as a system provider.

More and more customers are requesting integrated automation solutions, including robot integration, clamping fixtures, and CNC programming.

“We deliver production-ready systems – from design to commissioning,” says Settele.

Design, grippers, clamping technology, and programming all come entirely from in-house development – perfectly matched to every machining center.

Automation as the Key to Competitiveness

Labor shortages and rising wages continue to drive automation forward.

When skilled workers are in short supply, it becomes difficult to ensure consistent process quality.

“The steadily increasing minimum wage further fuels this trend, as it makes unskilled tasks such as loading and unloading the machine more expensive,” explains Settele.

This increases the pressure to integrate automation directly into the machining center.

Economic factors, coupled with rising demands on part quality, often make automation indispensable.

HG GRIMME therefore supplies turnkey systems precisely tailored to the available space, machine type, and the size and geometry of the parts.

Challenge: Workpiece Handling and Positioning

Workpiece handling remains one of the greatest challenges.

Parts must be stacked in such a way that their position can be detected by a camera, allowing the robot to feed them precisely to the machining center. HG GRIMME relies on specially developed gripper systems, intelligent image recognition, and optimized software programming.

When selecting robots, the manufacturer remains flexible – all major brands from Fanuc to ABB can be integrated. Particularly smooth integration is achieved with Fanuc robots in combination with Siemens or Fanuc controls, which are standard on every HG GRIMME machining center.

Precision Clamping Systems for Accurate Results

An essential component of every automation solution is the clamping technology. Stable placement of the workpiece on the worktable is crucial to ensure that each part is machined with identical precision.

HG GRIMME develops both the clamping systems and the corresponding CNC programs – everything from a single source.

Which Customers Benefit Most from These Automation Solutionslohnen

These solutions are ideal for customers machining thermoformed parts or composites made of glass or carbon fiber with batch sizes starting from around 50 pieces. Automation is particularly efficient in combination with tandem machines, where the machining center can be loaded in parallel with active machining time.

More Machines, Less Personnel – Maximum Efficiency

Companies operating multiple CNC machining centers benefit most from automation.

Instead of assigning one operator per machine, a single robot can supply several centers – fully automatic and highly efficient.

Automation Made in Germany

As a system supplier for production-ready complete solutions, HG GRIMME SysTech combines all competencies under one roof. Every CNC machining center is developed, manufactured, and tested at the company’s site in Wiedergeltingen, Lower Allgäu. Depending on complexity, the delivery time for an automation solution ranges from three to six months.

“We can retrofit existing machines at any time,” emphasizes Settele.

“Our customers receive a production-ready complete solution in which all components are perfectly matched – from the initial concept to the ready-to-run CNC machining center.

This comprehensive system expertise ensures smooth processes and maximum process reliability.”

Aluminium machining in the model making sector – CNC milling machine

Symbolising the progress that has been made in aluminium machining

More

5-axis rotary table milling machines

Hard work all round in Overath! The quality of plastic components depends very much on the mechanical finishing.

More