CNC model making milling machines:

Industrial machining of aluminium with the efficient

CNC machining centres from HG GRIMME SysTech

Aluminium’s low density makes it roughly two-thirds lighter than the steel which is conventionally used. It is very strong, has excellent forming properties and is also resistant to corrosion. Aluminium is therefore particularly suitable for manufacturing moulds and workpieces in industrial model making. For this purpose, the metal is initially roughly shaped as a block with a special CNC milling machine for aluminium.

Roughing and finishing –

Milling aluminium with a CNC machining centre

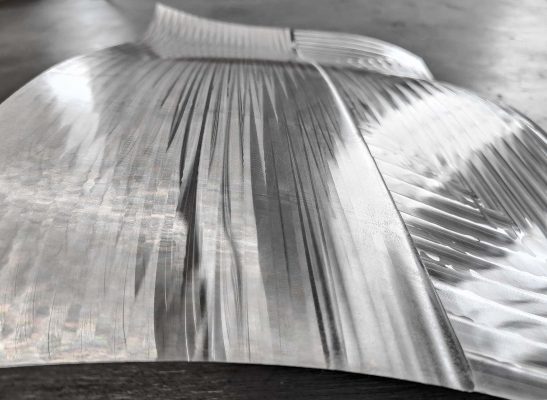

Roughing and finishing solid material – these are the two main steps for machining aluminium with a CNC milling machine. Roughing machines the block of aluminium in several steps to produce the rough outline shape. Material is removed on our CNC machines by high-speed cutting.

Step 1: Roughing aluminium

with our CNC milling machines

The smaller steps during roughing are balanced with a higher milling speed. Compared to a machine tool, our CNC milling machines achieve almost the same rate of material removal with roughing. Another advantage of this milling strategy using smaller steps: The roughing processes the aluminium block so it much more closely resembles the final size and shape of the component you want – and this saves time and effort in the subsequent finishing stage!

Step 2: Finishing with

the CNC milling machine

The rough-machined aluminium block is then finished. This step is particularly important because it is only this finishing that gives the metal block the details it requires to then be used in industrial model making. With this CNC machining of aluminium, our CNC machining centres operate at a high feed rate and high milling speed. This means that HG GRIMME SysTech CNC milling machines used in model making produce an excellent surface finish and a very precise detailed shape. As the roughing process has already been performed, our CNC machines only need to remove a small amount of material during aluminium cutting or finishing.

CNC model making milling machines

from HG Grimme SysTech –

your benefits at a glance

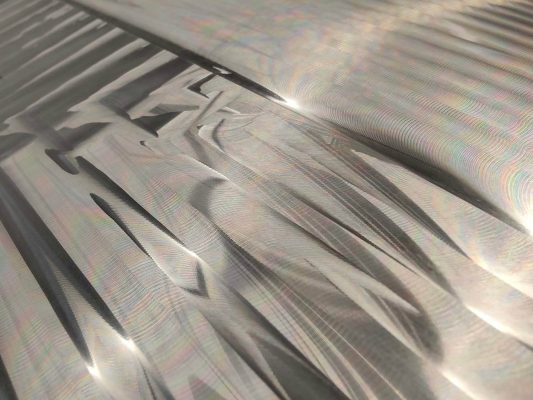

Aluminium machining produces chips which during milling may cake onto or weld onto the edge of the cutting tool (known as a built-up edge). To prevent such a built-up edge, we apply a minimal amount of lubrication from the outside or from the inside through the cutting tool. The lubricant used to provide the minimal lubrication is either based on vegetable oil or a solvent-containing substance which ensures that the chips cannot stick to the cutting edge.

Work safely with CNC milling machines – machining centres with a cabin, extraction and filter

Particularly when you are using lubricants which contain solvents, it is essential to protect your employees because the solvent is finely atomised and can thus quickly get into the respiratory tract. When you choose a CNC machining centre from HG GRIMME SysTech, your employees and the general working environment are extremely well protected because each of our CNC milling machines for machining aluminium has a special cabin which completely encloses the working area and thus prevents the atomised solvent from escaping – because the machining only takes place inside the enclosed cabin. A built-in extraction system ensures that the lubricant is already removed from the cabin during roughing and finishing. At the same time, the air is purified via a filter.

Yes, thanks to high-speed cutting, our CNC systems achieve greater efficiency and cost savings compared to conventional machine tools with flood cooling. Production is accelerated for the same volume of work. In addition, our machines enable seamless switching between aluminium and other materials, such as plastics or lightweight materials, without requiring extensive cleaning processes.

The process begins with roughing, where the aluminium block is roughly shaped using high speeds and small steps for fast and precise pre-forming. This is followed by finishing to achieve a fine surface and exact contours. This two-stage process ensures high-quality surfaces and dimensional accuracy, making it ideal for model making and precision components.

When milling aluminium, built-up edges can occur due to friction, which negatively affects surface quality and tool life. Minimum quantity lubrication—whether based on vegetable oil or solvents—prevents material from sticking to the cutter and ensures optimal cooling and lubrication. Our CNC machines are equipped with enclosed cabins, extraction, and filtration systems to guarantee a safe and clean working environment.

Our CNC machining centres offer high flexibility: switching to plastics or other lightweight materials is possible at any time. Unlike conventional machines with flood cooling, there are no issues with residues or contamination. This flexibility optimises production efficiency and cost-effectiveness, even with frequent material changes.

Protecting employees is our top priority: all machines are equipped with fully enclosed cabins, extraction, and filtration systems. This keeps solvents and fine aluminium chips out of the breathing air. Continuous air filtration ensures a safe and clean working environment, even when using solvent-based lubricants.

HG GRIMME SysTech offers CNC milling machines for aluminium in various sizes and versions—from compact units for model making to large machining centres for industrial applications. Examples include space-saving 5-axis CNC milling machines and high-dynamic models with large work tables and high load capacities. All variants combine precision, flexibility, and efficiency and can be individually adapted to your requirements.HG GRIMME SysTech offers CNC milling machines for aluminium in various sizes and versions—from compact units for model making to large machining centres for industrial applications. Examples include space-saving 5-axis CNC milling machines and high-dynamic models with large work tables and high load capacities. All variants combine precision, flexibility, and efficiency and can be individually adapted to your requirements.

Inexpensive and incredibly flexible – switch material at any time

CNC milling machines from HG GRIMME SysTech are about half the cost for machining aluminium in comparison to machine tools that use splashing water. And this is while still producing the same volume of work! In addition, our CNC machining centres are not just restricted to roughing and finishing aluminium. You can switch material at any time – for example to plastic or lightweight materials. This is something that conventional machine tools that use splashing water often cannot do because plastics contaminate the water and therefore the machines too. By comparison, CNC milling machines from HG GRIMME SysTech offer you maximum flexibility at the best price and are thus much more profitable – even if you really do just want to machine aluminium.

HSC milling machines – how you

benefit with HG Grimme SysTech

Our CNC machining centres can operate at up to 30,000 rpm – an impressive figure that allows you to achieve powerful high-speed machining when you mill aluminium using CNC technology. The high speed of the spindle produces a higher feed rate during high-speed cutting – so the tool of our CNC milling machine passes the material much more often over the same period, saving a significant amount of time. This is possible due to the lower weighting of the axes which allows our CNC machining centres to achieve a faster feed rate, so accelerate faster, compared to machine tools. The only limit is imposed by the material and the cutting tool.

Save time with

high-speed cutting

When a CNC machining centre from HG GRIMME SysTech is used, the only thing that changes when milling aluminium for model making is the milling strategy – the outcome in terms of the quality of the finished product remains the same! The smaller steps during roughing produce a better final shape of the workpiece faster and this means the finishing process takes less time. In addition, our CNC milling machines are much cheaper compared to a machine tool and thus instantly pay dividends for you! Impressed? Then here you will find all the CNC milling centres that can be used for machining aluminium in industrial model making:

CNC machining centres for aluminium – a selection

The compact gantry milling machine for aluminium machining

The CNC machining centre for series machining of aluminium with a minimal amount of lubrication.

More

CNC milling machine universal with gantry design

A universal powerhouse with a rapid traverse of 80 m/min. Tools can be changed at any time on the G-S-F/Universal.

More

CNC machining centre for small workpieces

The answer for effective milling of small workpieces. A real multi-talent thanks to the double-shaft spindle and automatic tool changer.

More

Aluminium machining with our

CNC machining centres

Here you will find all CNC milling centres for model making