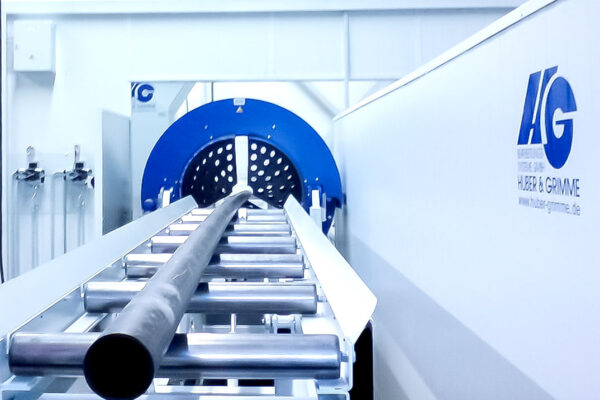

CNC Machines for Plastic Pipes and

Pipe Systems Made of Aluminium

Precise Production Solutions for Pipe and Plastic Processing

The requirements for the production of plastic pipes and pipe systems are constantly increasing – both in terms of dimensional accuracy and with regard to production speed and flexibility. Whether PE, PP, PVC, PVDF or technical thermoplastics: modern pipe systems must be reliable under pressure, resistant to temperature, and media-tight. HG GRIMME SysTech offers you the right CNC machine for plastic pipes – custom-engineered, powerful, and precisely tailored to your processes.

Advantages

Our CNC Solutions for Pipe Processing

- 5-axis technology for complex machining of rotationally symmetrical or freeform plastic components

- Large machining volumes for long pipes, half-shells, or voluminous molded parts

- Automation options through tool changers, intelligent clamping systems, CAD/CAM integration, and industrial robot connectivity

- Wide range of materials: Suitable for PE, PP, PVC, PVDF, aluminium, and more

- Custom machine concepts for your specific requirements

Typical Applications

CNC machines in the pipe industry and pipeline construction. Our machines are used in numerous areas of pipe and plastics processing:

- CNC machining of plastic molded parts, adapters, flange connections, and aluminium components

- Post-processing of thermoformed pipes or half-shells

- Pipe processing in pre-fabrication or final assembly

- Production and adaptation of connectors for pipe systems

- Milling, drilling, chamfering, and contouring – precise and automated

Your CNC Machine – Developed for Your Pipe Production

Our systems are not off-the-shelf standard machines. Each CNC machine is designed according to your requirements – adapted to installation space, workpiece type, material, and desired level of automation. Either from our modular system with around 365 options or as a completely new machine concept. This ensures future-proof and cost-effective processing of plastic pipes or aluminium pipe systems.

Our engineering and manufacturing expertise enables short project lead times and direct communication – from the initial idea to the turnkey system.

Find the complete overview of all machines here

Every machine is individually adaptable to your application

Contact our sales team

Get in touch – no obligation. We provide fast and personal advice.

More

Everything about machine planning

Each machine passes through many departments. Learn more – from planning to production and service.

MoreTechnical Features

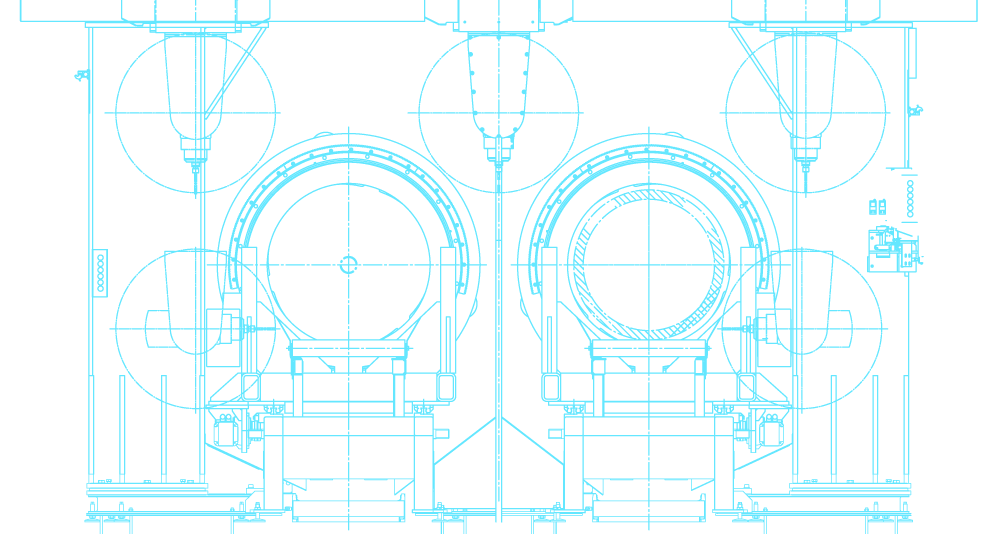

Our CNC machines for the processing of plastic pipes:

- Portal milling machines and gantry systems with robust construction for low-vibration machining

- Machining areas several meters long and load capacities over 800 kg

- CNC rotary table machines for smaller workpieces

- High-frequency spindles up to 15 kW and 36,000 rpm

- Automation options for efficient series production

- Fanuc, Siemens, or NUM control systems with CAD/CAM integration

- Modular machine design for maximum adaptability

Trust Through Experience

Mechanical Engineering by HG GRIMME SysTech

- Over 30 years of experience in custom CNC machine building

- Industry expertise in plastics processing and the pipe sector

- Complete solutions from a single source – design, assembly, commissioning, and technical service

- Maintenance, service, training – for long-term reliable production

- “Made in Germany” – precision, quality, and durability

CNC Machines for Pipe Systems – Plastic Pipes and Aluminium Pipes

Our CNC milling machines and 5-axis machining centers are specially developed for the processing of plastic pipes and molded parts. Thanks to well-thought-out machine architecture and state-of-the-art control technology, they enable precise machining of components with complex geometries – from single parts to series production.

Whether molded parts, flanges, T-pieces, or bends: our CNC machines enable demanding machining tasks with the highest surface quality and repeat accuracy – even for large workpieces

Start Your CNC Project for Plastic Pipes Now

Our experts are happy to advise you on the right

CNC machine for plastic pipes – individual, practical, and efficient.

📞 Phone: +49 8241 96080

📧 Email: sales@hg-grimme.de

🌐 www.hg-grimme.de

Best Practice

HG GRIMME SysTech – swissplast en

HG GRIMME SysTech and swissplast group – the similar mentality of the two family-owned companies plays a role, as can be seen at the Gotha location.

More

ASGLAFORM increases vertical range of manufacture with CNC machine from HG GRIMME SysTech

CNC milling machine in portal construction

More

Krüger Aviation relies on HG GRIMME SysTech

Take-off in partnership. When the cycle time is halved…

More