From the initial design to the finished machine – we provide everything

News & Events

CNC stock machines, quickly available CNC machines

Request now – CNC milling machines in stock

Automotive

Composite materials

Major order for machining carbon fibre

Milling premium plastics

5-axis rotary table milling machines

Automotive

CFRP Processing – ACE Advanced Composite Engineering GmbH and HG GRIMME SysTech

Aviation

Krüger Aviation relies on HG GRIMME SysTech

Manufactured in Germany,

used all over the world

As a manufacturer of cnc milling machines, cnc cutting machines and fixtures, our name is synonymous with pioneering engineering that meets every conceivable requirement. We build powerful, innovative CNC machining centres for sophisticated processing of plastics and composite materials. With a few modifications, our powerful CNC milling machines are also capable of processing aluminium, wood and other modelling materials.

HG GRIMME is renowned for its high-precision technologies, durable and compact high-tech machines, and individual designs, created using CAD/CAM programs. From the initial design through to completion, we handle every single step ourselves at our factory in Wiedergeltingen. This is the only way we can guarantee our CNC machines are the very best quality – Made in Germany. The finished machines are then transported to our customers and are used all over the world. With maximum, reliable precision and dynamics.

When you choose a milling machine from HG GRIMME, you benefit from top-notch engineering and our more than 30 years of experience working with CNC machining centres. From when the company was founded in 1987 to the present day, we have designed and manufactured our milling machines by embracing maximum precision, robust designs and technical innovations that satisfy every single requirement.

Quick Answers: CNC Machines – Fast Facts

HG GRIMME SysTech develops and manufactures high-quality 5-axis CNC milling machines, CNC machining centers, and custom CNC machines. Our product range includes different machine types such as portal milling machines, gantry systems, and 5-axis CNC rotary table machines.

These terms are often used in different ways but describe various aspects of modern manufacturing technology.

A CNC system generally refers to the entire setup — including multiple CNC machines, the control unit, peripheral equipment, and sometimes automation solutions.

The term CNC machine is more general and refers to any computer-controlled machine, such as milling or cutting machines, or other technologies.

A CNC machining center is typically a high-performance milling machine that allows several operations — such as milling, drilling, or tapping — to be performed in a single setup. It is usually equipped with an automatic tool changer and other advanced features.

A 5-axis milling machine is one where the tool or the workpiece can move simultaneously along five axes. This enables fully three-dimensional (3D) machining of complex geometries. All of our machines feature at least 5, 6, or even more axes.

At HG GRIMME, 5-axis CNC milling machines and CNC machining centers are generally identical, as they always combine multiple machining processes such as milling, drilling, and tapping. Internally, we often use the two terms interchangeably — the difference lies mainly in individual naming preferences among our colleagues.

In short, for our machines: All 5-axis CNC milling machines are also CNC machining centers, equipped with at least 5 axes — often 6 or more.

Which materials can be processed with HG GRIMME SysTech CNC machines?

Our CNC machines are designed for precise machining of plastics, composite materials such as carbon fiber (CFRP) and glass fiber (GFRP), model-making materials, and aluminum. They enable efficient and accurate production of workpieces in various sizes.

We provide turnkey automation solutions for CNC machines – from consulting and planning to the integration of robotics (industrial robots, cobots), fixture construction, clamping technology, and suitable software for efficient and flexible manufacturing.

All-round personal service

Whether you have questions about your HG milling machine or would like to ask us to develop an individual CNC milling machine for you, we are there to support you every step of the way from design and manufacture through to acceptance and ongoing maintenance. Whatever your CNC machining centre involves, our customer service team covers all aspects and will offer you personal, rapid assistance.

From planning to commissioning

Eye-to-eye cooperation

with over 30 years of experience

in mechanical engineering

From a CNC machining centre

to a thermoforming machine:

We are a leading manufacturer of CNC machining systems for processing and finishing plastics, composite materials, modelling materials and aluminium.

Every material presents different machining demands. Whether you want to mill plastic and aluminium, cut composite materials or work with materials such as foam, wood or even leather – HG Grimme can offer you the perfect solution for any type of material and size of component! As well as CNC milling machines, or cnc blade cutting machines, our range also comprises thermoforming machines and fixture construction to ensure optimum fixing of the workpiece. Explore the wide range of machines and process technologies we have to offer:

Machining centres

Our range comprises precise CNC milling machines with a rotary table, gantry or portal design – from compact milling machines to huge CNC systems.

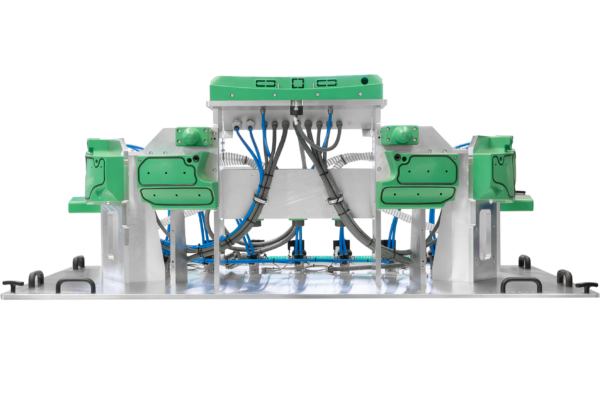

Fixture construction

We construct milling fixtures to allow components to be fixed precisely and develop the appropriate milling programs for your workpiece.

Process technology

CNC milling machines and cnc blade cutters through – we offer the right process technology to suit your CNC machine.

Thermoforming machines

Our thermoforming machines allow you to cover the full production cycle with vacuum forming, press forming or twin sheet forming.