Maximum flexibility and efficiency –

Our CNC milling centres and their designs

Our range includes versatile CNC milling machines and CNC machining centers featuring a modular design with numerous configuration options.

This allows every machine to be individually adapted to the size of the workpiece and the specific material requirements — from enclosed work areas with a roof to extraction systems or partition walls for tandem operation.

In addition to our standard models, we also develop custom CNC solutions within our special-purpose machine construction division at HG GRIMME SysTech.

Questions about CNC designs: Portal, Gantry, or Rotary Table?

The main difference lies in how the table and the machine move:

In a portal design, the workpiece sits on a table that moves forward and backward. The tool — the spindle with the milling cutter — is mounted on a large “portal” above the table. The spindle moves up and down along the so-called Z-axis and travels sideways across the workpiece. The movement in the longitudinal direction — forward and backward — is performed by the table. The portal design is particularly suitable for very large and heavy workpieces, as the table is solidly supported and the portal allows for highly precise tool movements.

In a gantry design, the table remains fixed in place during machining and does not move. The spindle, which holds the milling tool, is mounted on the Z-axis, which in turn is attached to a movable crossbeam. This crossbeam provides the forward and backward movement, while the Z-axis guides the tool sideways and vertically. As a result, the milling tool can move in all relevant directions across the workpiece without the table itself having to move. Overall, this design requires less floor space and tends to be simpler in structure.

The rotary-table design differs from the portal and gantry designs through its especially compact construction and unique movement concept.

The rotary table turns during milling and can also move longitudinally — that is, forward and backward. Unlike the gantry design, where the table remains stationary, and the portal design, where the table moves in only one direction, the rotary table combines multiple movements in one unit.

The Z-axis — similar to the portal design — is fixed in place and moves the tool vertically as well as sideways over the workpiece. The table is designed for workpieces of up to around 200 kg and enables precise 5-axis machining within a compact footprint.

The rotary-table design is particularly suitable for smaller workpieces, for applications where the installation site changes frequently, or when space is limited — as the machine is easy to transport and quickly ready for operation again.

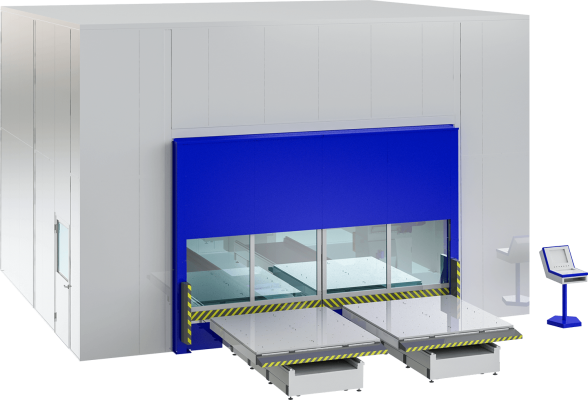

For small to

medium-sized workpieces:

The rotary table design

The compact design of this machining centre means that workpieces can be machined very quickly and with accurate contours. The rotary table design is suitable for smaller to medium-sized milling attachments and shaped parts. The machine table of the system can withstand a load of up to 200 kg.

The CNC rotary table machining centre is a compact system. It consists of the actual milling machine with the machining axes and the machine cabin. It can be equipped with a roof and given optimum protection from milling dust with a dust protection package. Compared to other systems, the CNC rotary table milling machine can quickly be moved to a new operating site. The CNC milling machine can swiftly be set up in its new location, keeping the machine downtime to an absolute minimum.

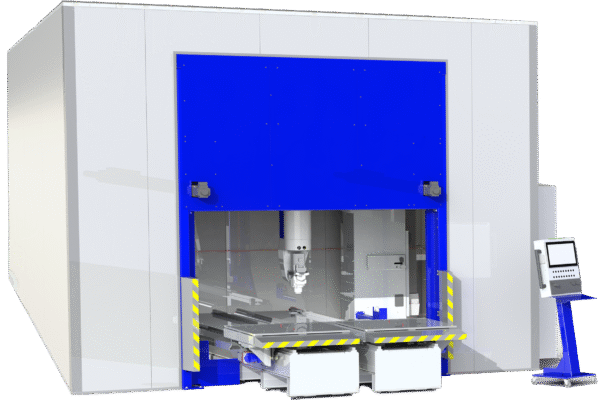

With permanently

integrated machine table:

The gantry design

With the gantry design, the three linear movement axes are assigned to the machine portal. If the machine has fixed stands with a moveable crossbeam overhead, one refers to a bridge gantry design. In comparison to the portal design, this is the cheaper design because the table is permanently integrated and does not require a drive. It is possible to operate in tandem here with a permanently integrated table, similar to a two-table portal machine, by dividing up the working space with a partition.

The fitting takes place within the machining space of the machine. The permanent table means the amount of space required is fundamentally smaller than with a portal machine. However, this does not mean that we are restricted in terms of component size. Our CNC bridge gantry milling machines can, for example, have table sizes with a length of 8 m and a permanently installed table. If you want to equip components outside of the cabin, a shuttle table is always another option.

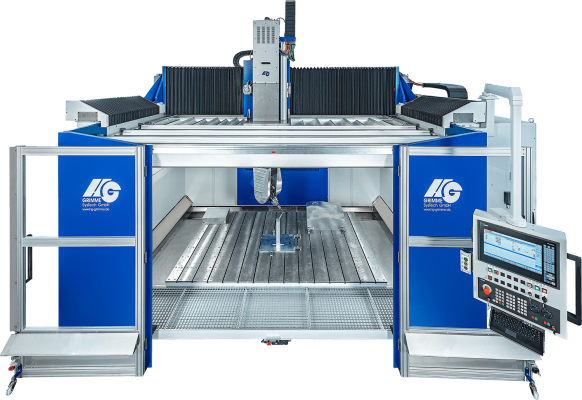

For large workpieces

and impressive results:

The portal design

A portal machine is suitable for large workpieces and for producing the most impressive work results at the same time. Portal systems can be equipped as a single or twin-table machine. With this design of machine, the workpiece table is flat and the machine has a high level of stiffness. The table(s) move along the longitudinal axis and by contrast the workpiece moves along the rest of the axes. In general, the portal design offers a high level of static and dynamic stiffness due to the great mass.

CNC machining centres with a portal design can also be equipped with a heavy Z-axis spindle combination which can then work with incredible precision owing to the overall concept and the mass. The main spindle is mounted on a portal carrier which is supported on both sides. The assignment of shaped parts to the machine tables can be done from outside the working space.