HG GRIMME SYSTECH – CNC Machine Overview

Experts are always available to advise you, even without an appointment,

at ☎ +49 8241 96080 or via email ✉ sales hg-grimme.de

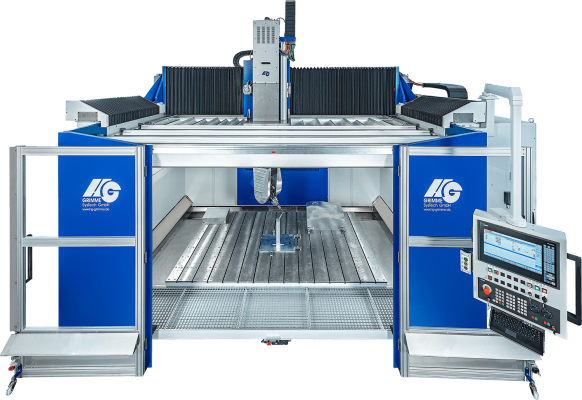

CNC Milling Machine RT-F 1400

Compact machine for efficient milling of small workpieces

CNC Milling Machine RT-F DUO

Synchronous milling with two milling spindles, two shuttle table levels, and four rotary tables

CNC Milling Machine G-S-F/B

Bestseller and entry-level model, suitable for tandem operation due to partition wall

CNC Milling Machine G-T-F/M2Z

High-performance CNC milling machine for milling aluminum with two independent axis groups

CNC Milling Machine G-T-F/S

With single or tandem shuttle table, loading outside the CNC machine

CNC Milling Machine G-S-F/M

For oversized XXL components or complete models, the CNC bridge gantry stands for absolute precision

CNC Milling Machine G-S-F/MK

Roughing and finishing with minimum quantity lubrication and highest precision, heavy-duty steel machine table

CNC Milling Machine G-S-F/UNI

Universal powerhouse for all materials – CNC machine with powerful 15 kW milling spindle

CNC Milling Machine G-DT-F/SB

Inclined bed, rotary table with milling space and extraction against dust, perfect for composite materials

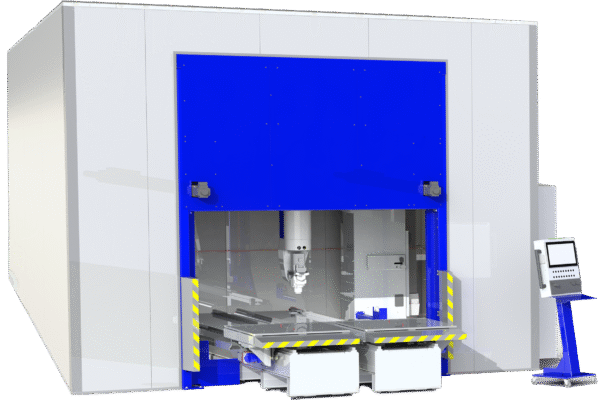

CNC Milling Machine P-T-F

Portal milling machine for single or tandem operation, with or without safety cabin

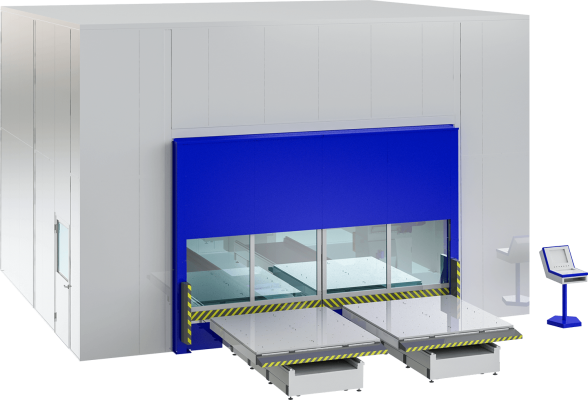

CNC Milling Machine P-T-F/M

CNC machine in portal design, with one or two shuttle tables

Multi-channel CNC Machines

CNC machines with multiple assemblies and cycle times that are difficult to achieve with two machines and two passes

CNC Cutting Machine G-S-K

Razor-sharp cuts, invisible predetermined breaking lines, precise weakening to residual wall thickness | 6-axis CNC machine

Thermoforming Machine

Thermoforming with the eidos thermoforming machine

Good to Know & FAQ

How do I find the right CNC machine for my application?

Our experts provide you with individual advice from the very beginning and support you in selecting the right CNC system according to your workpiece size, material requirements, and production environment. Learn more about the development of your CNC machine -> here.

Our CNC machines are designed for processing aluminium, plastics, a wide range of composite materials such as CFRP, GFRP, prepreg, and honeycomb, as well as model-making materials and many other materials.

Yes, we offer both modular CNC systems and custom special solutions that are tailored exactly to your needs and specifications.

Our CNC machines can be equipped with automation solutions such as industrial robots, cobots, automatic clamping devices, and camera-based component recognition. Find more information -> here.

Our solutions are used in the automotive industry, aviation, logistics, leisure industry, pipe system technology, sanitary, boat building, and many other sectors.

From the initial consultation through planning, design, and manufacturing to commissioning and after-sales service, we accompany you throughout the entire process. User reports can be found -> here.

Our technical service is characterized by fast response times, direct accessibility, and personal support. When you contact us, you always speak immediately with a competent contact person – without any waiting loops. Fault diagnosis is handled efficiently via phone, remote maintenance, TeamViewer, or common tools like Skype and Teams. If necessary, you can also simply send us pictures or videos of your issue, so that solutions can often be found remotely. Find more information here.

Experts are always available to advise you, even without an appointment, at ☎ +49 8241 96080 or via email ✉ sales@hg-grimme.de

What our customers say

Together with our customers, we report on the successful use of CNC milling centers or blade processing centers. In the User Reports section, you will find a selection of successful projects.

Our CNC machining centers from 5-axis and up are specifically or modularly planned for each individual customer and adapted to the respective industry, space, and material requirements. Each CNC machining center from HG GRIMME SysTech is unique due to the wide range of options. With us, you get everything from planning to production from a single source and Made in Germany.